Paved Surfaces

Paved Surface Drainage Installation

A. Excavation

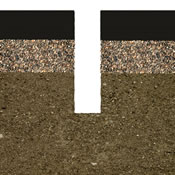

1. Trenching

Preferred method – rock wheel trencher

In conditions where the soil exhibits sufficient cohesion, a rock wheel trench can be used to excavate a 4 to 6 inch wide trench through the pavement and through base material to the specified depth.

If the trench walls do not cave in, undermining the structural integrity of the base, this is the method of choice. This results in less surface scarring, less backfill, and less pavement to replace.

2. Alternate method

In conditions where the base aggregate is loose or less compacted, a chain trencher might be required.

- Saw cut or disc cut to provide a uniform edge.

- Take out the pavement to a width that prevents undercutting of the pavement during trenching and for effective compaction after the backfilling.

- Remove the excavated pavement from the site.

- Use a chain trencher to form a 4 to 6-inch trench to the specified depth.

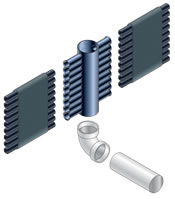

B. Connection of collection system to transport system

Procedure for connecting the Multi-Flow collector lines to the transport system may be specified by the designer. It is likely to be one of these two methods.

1. Preferred method

If the elevation of the outlets allows for it, locating the transport system below the collector system has several benefits. This method increases flow performance and reduces the risk of rehydration of low-lying areas.

When the transport system is located below the collector system, Multi-Flow multi-purpose connectors are used to outlet the Multi-Flow collectors.

2. Alternate method

If the site includes elevation constraints, the transport system can be located level with the bottom of the collector system.

When the transport system is located at the same level as the bottom of the collector system, end outlets or side outlets are used to outlet the Multi-Flow collectors.

3. The geotextile filter should be securely taped to all connectors with wide pipe tape. This assures that debris will not infiltrate behind the fabric at these transition points.

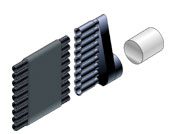

C. Backfill and consolidation

1. Backfill will be accomplished using select, washed, very coarse sand as specified.

2. Position Multi-Flow in the center of the trench and assure that backfill material extends from the bottom to the top of the trench on both sides of the product.

3. Thorough and effective consolidation is vital. Saturation of the previously backfilled trench is the preferred method to achieve consolidation. A 1-inch, low-pressure stream of water applied to the top of the backfilled trench is adequate in most situations.