About Multi-Flow LDVS

What it is.

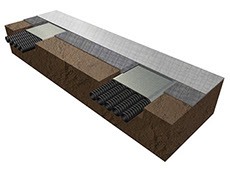

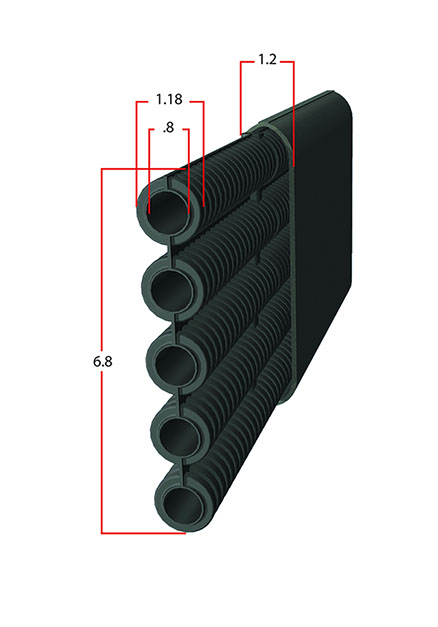

Multi-Flow is a closed core geocomposite drain made from HDPE. The flow channels are corrugated for strength, perforated for rapid infiltration, and interconnected for redundancy and performance. The resulting product is strong, lightweight, flexible and an excellent conduit for fluids and gases. It’s rounded shape eliminates sharp edges, making it easy on liners.

Multi-Flow LDVS is a significant step ahead of other systems due to its propriety shape and method of connection. When combined with easy-to-use connectors and standard pipe sizes, the leak detection vent system outperforms other systems, and at a low cost.

6″ Multi-Flow comes compact in 150 ft. rolls

How it Works.

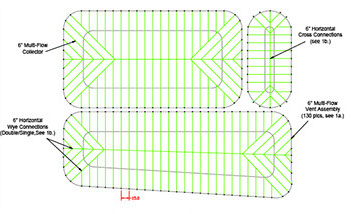

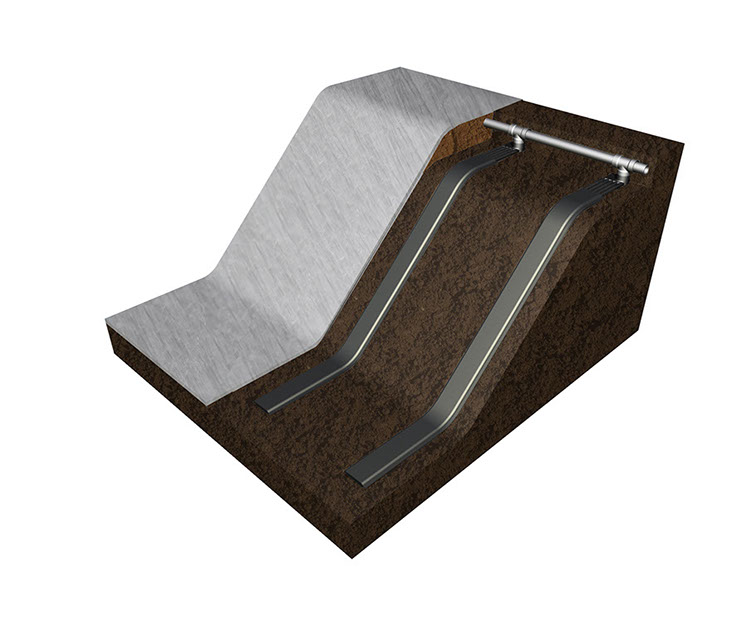

When fully assembled, Multi-Flow LDVS is quite simply a series of collector lines, spaced incrementally, and connected to drains on the low end and vents on the high end.

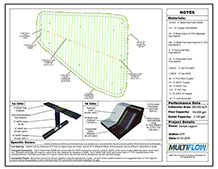

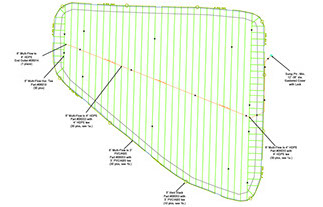

The system is designed for your project based on the rough layout, shape, size, and slope of the site. Next, decide the best way to vent on the high end, drain on the low end and slope everything accordingly. The system can be as simple or advanced as necessary by adding additions such as a leak detection sump, forced venting or telemetric.

1. System Layouts & Design

Typically, Multi-Flow LDVS is designed with a common-sense approach to gravity and slope. Following the contours of the pond or lagoons, collector lines are oriented in the direction that offers a path of least resistance to the high-point and low-point. Lines should be spaced for continuous coverage on 15 ft-20 ft intervals, making use of connectors and manifolds to achieve an efficient grid for collection and removal of fluids and soil gases.

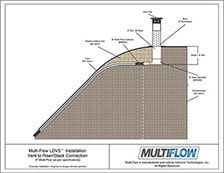

2. Venting Design

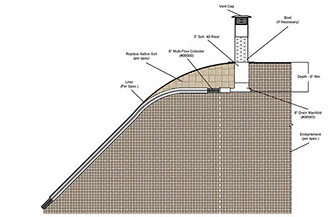

Multi-Flow is installed under the liner to provide a flow path for gases and liquids preventing damage caused by lifting or tearing of the liner. The top end of the system is vented to the atmosphere or collected in a manifold. If desired, positive venting (blower units) can also be added to outlets to aid diurnal atmospheric pressure changes in removing gases.

Multi-Flow lines can be rolled out over the prepared surface and covered by the pond liner. This method avoids the need for trenching and it locates the Multi-Flow right where methane and other gases are most likely to accumulate. If a completely smooth liner is desired, installers can create a depression without piercing the liner in many locations.

Vent Stacks are commonly used to vent collected gases to the atmosphere, while protecting the system from the elements. They are typically placed around the perimeter of the liner and are connected at the highest point of the collector lines. It is compatible with PVC/Sch 40.

Manifolds can be used to connect vents to a perimeter system without piercing the liner. A small amount of excavation replaces many individual liner boots and can be connected where convenient.

Covered Vent

Riser Pipe

6” Multi-Flow Riser Manifold

3. Drainage Design

The low point of the Multi-Flow System is typically connected to piping which leads to a pumping or monitoring pit, or discharge location. This pit, located outside of the containment area, allows ground water to be removed from under the liner with a variety of pumping/piping options. Most importantly, it offers a leak detection/inspection point as well.

4. Leak Detection

Multi-Flow LDVS provides a leak detection option. Simply connect the drain outlet to a sump pit with a pump and any required pumps, monitors or telemetrics. Then, the users may monitor and test any fluid below the liner, alerting them of problems before they become worse and/or more costly.

Example Sump pit w/ pump and monitoring equipment

Why it Works.

Multi-Flow LDVS is the most versatile, effective and affordable option for protecting your synthetic liner. Beyond that, we, at Varicore Technologies, provide service and support for your individual project, supplying ultimate value to the systems.

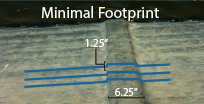

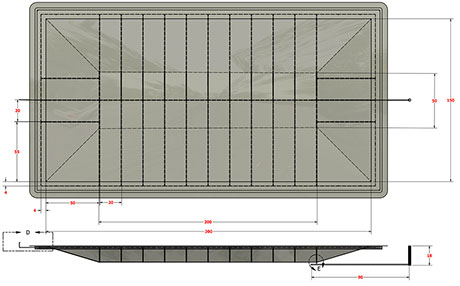

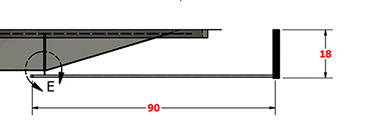

Multi-Flow LDVS is a product with quality design, made of quality materials. Fully-enclosed flow channels made of HDPE, corrugated for strength and wrapped in an industrial-grade 4 oz. polypropylene non-woven needle punch fabric. System profile is compact, strong, and easy to use. Round flow channels maximize surface area, collect water quickly, and flows efficiently… the same can be said for collected gases moving towards the vent. System coverage is maximized by redundancy and modularity, making it simple to adapt into projects of almost any size or scale.

The cost associated with a synthetic liner is significant, it should be protected. As opposed to covering every sq ft of the affected area, Multi-Flow LVDS uses a more compact and efficient design, resulting in a much smaller footprint. Yet it provides results that outperform previous methods of draining and venting underneath synthetic liners. Multi-Flow LDVS Systems are designed to adapt to each project, while easily connecting and adapting to standard pipe sizes and types, further enhancing the cost-effective benefits.

We want to ensure that your project is not only successful, but that the experience during the planning phase is as stress-free as it can be. Our team of technical experts stands ready to provide anything from consulting, design, layout, specifications and proposals…all free of charge. We are even available for on-site consulting and installation overview. This is a rapidly-developing and changing market. We adapt quickly and make the process of implementing Multi-Flow LDVS as easy as possible.

Protect your project and your customers’ investment with Multi-Flow LDVS, the name in synthetic liner protection.